The world of merchandise printing is rapidly evolving, and businesses seeking to stay ahead of the curve must embrace the latest advancements in the industry. Two technologies that are poised to revolutionize the way we approach custom merch are UV printing and DTF (Direct-to-Film) technology. At OreletPrint, we are excited to offer these cutting-edge solutions to our clients, empowering them to elevate their designs and streamline their workflow.

Understanding UV Printing

UV printing, or ultraviolet printing, is a process that utilizes specialized inks and a high-intensity UV light to instantly cure the ink on a wide range of materials, including fabrics, plastics, and even metals. This technology offers several advantages for merch printing:

Advantages of UV Printing

- Vibrant, long-lasting colors: UV inks produce exceptionally vivid and durable prints that resist fading and wear over time.

- Versatility in material compatibility: UV printing can be applied to a diverse array of substrates, allowing for greater creative freedom in product design.

- Rapid turnaround times: The instant curing process of UV printing enables faster production and quicker delivery to customers.

- Improved efficiency: UV printing eliminates the need for traditional drying or heat-setting processes, streamlining the overall production workflow.

Limitations and Considerations

While UV printing offers numerous benefits, there are a few factors to consider. The initial investment in UV printing equipment can be higher than traditional methods, and the inks themselves may be more expensive. Additionally, the process may be limited in its ability to handle certain textured or uneven surfaces, requiring careful planning and execution.

Exploring DTF (Direct-to-Film) Technology

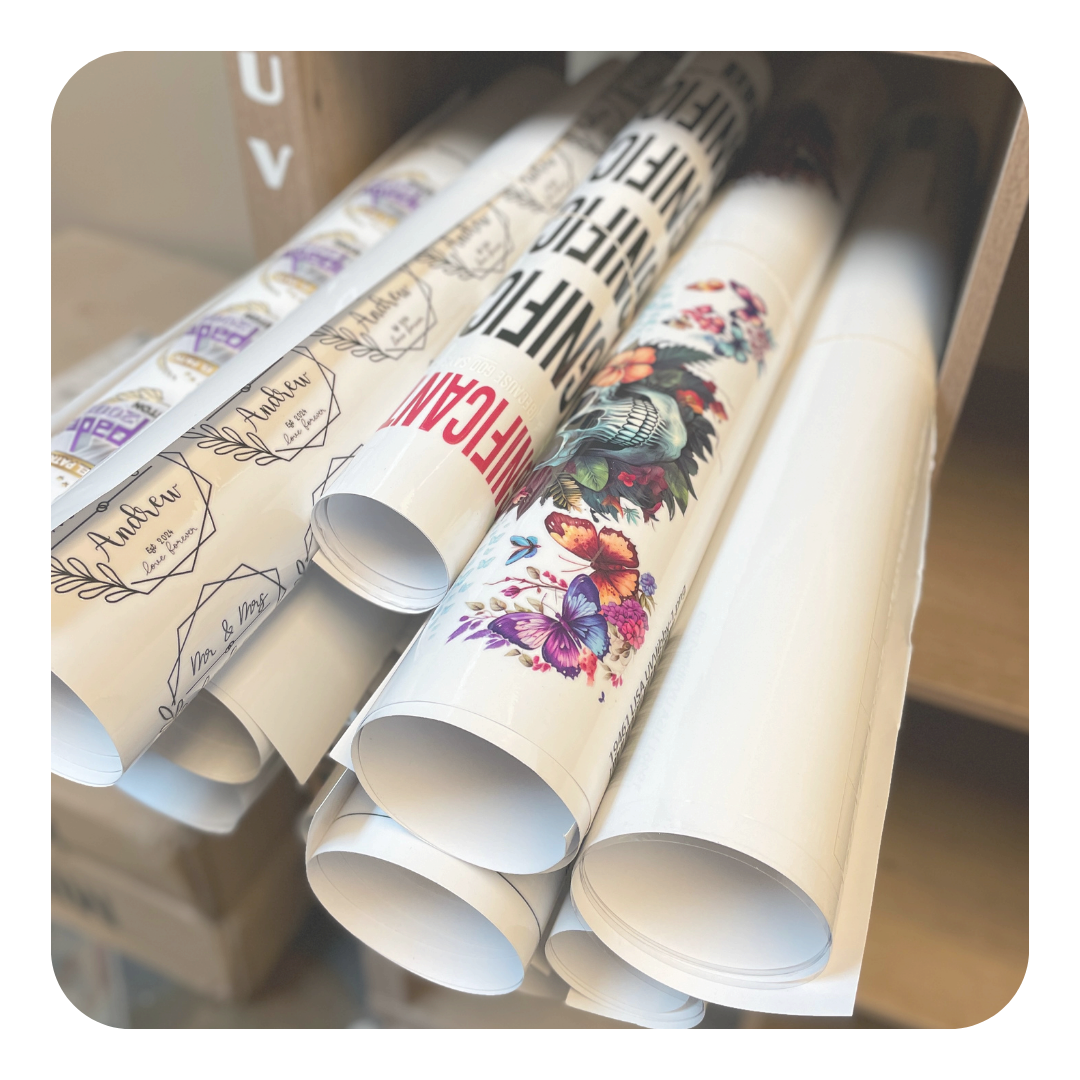

DTF, or Direct-to-Film, is a revolutionary printing technique that has gained significant traction in the merch industry. This process involves printing the design onto a specialized film, which is then transferred onto the desired substrate, such as apparel or accessories.

Benefits of DTF Printing

- Exceptional print quality: DTF technology produces vibrant, high-resolution prints that rival traditional screen printing methods.

- Increased versatility: DTF can be applied to a wide range of materials, including cotton, polyester, and even leather, expanding the creative possibilities for custom merchandise.

- Cost-effective production: DTF eliminates the need for costly screen-printing setups, making it a more accessible option for small businesses and startups.

- Faster turnaround times: The DTF transfer process is typically quicker than traditional printing methods, allowing for faster delivery to customers.

Potential Drawbacks and Challenges

While DTF offers numerous advantages, there are a few potential drawbacks to consider. The initial investment in DTF equipment and supplies may be higher than some traditional printing methods. Additionally, the durability of DTF prints may be a concern, particularly for high-wear items, requiring careful consideration of the end-use application.

Comparing UV and DTF Technologies

When it comes to choosing between UV printing and DTF, businesses must weigh the unique benefits and limitations of each technology to determine the best fit for their specific needs.

Print Quality and Durability

Both UV printing and DTF offer exceptional print quality, with vibrant colors and sharp details. However, UV prints are generally considered more durable and resistant to fading over time, making them a suitable choice for high-wear merchandise.

Versatility and Material Compatibility

UV printing boasts a wider range of material compatibility, allowing for printing on a diverse array of substrates. DTF, on the other hand, is primarily focused on apparel and textile-based products, offering a more specialized solution.

Cost-Effectiveness and Production Speed

DTF technology is often more cost-effective, particularly for smaller production runs, as it eliminates the need for costly screen-printing setups. UV printing, however, may offer faster turnaround times due to its instant curing process.

The Impact on the Merch Industry

The emergence of UV printing and DTF technology is transforming the merchandise printing landscape, empowering businesses to offer their customers unprecedented levels of customization and efficiency.

Increased Customization Options

These innovative printing methods allow for greater creative freedom, enabling businesses to produce unique, one-of-a-kind merchandise that resonates with their target audience.

Improved Efficiency and Turnaround Times

The streamlined workflows and rapid production capabilities of UV and DTF printing translate to faster turnaround times, allowing businesses to respond more quickly to market demands and customer needs.

Expanding Market Opportunities

By offering cutting-edge printing solutions, businesses can tap into new market segments and reach a wider customer base, positioning themselves as industry leaders and innovators.

OreletPrint's Offerings

At OreletPrint, we are proud to offer our clients the latest advancements in merch printing, including custom transfers, UV printing options, and DTF gang sheets. Our team of experts is dedicated to helping businesses navigate the evolving landscape of the industry, ensuring they have the tools and resources they need to succeed.

Future Trends and Innovations

As the merch printing industry continues to evolve, we can expect to see even more exciting developments in the years to come. Emerging technologies, such as sustainable ink formulations and automated production systems, will likely play a significant role in shaping the future of the industry.

Conclusion

The future of merch printing is undoubtedly bright, and businesses that embrace the power of UV and DTF technologies will be well-positioned to thrive in the years ahead. At OreletPrint, we are committed to empowering our clients with the latest innovations, helping them elevate their designs, streamline their workflows, and unlock new opportunities in the ever-evolving world of custom merchandise.