In the dynamic world of custom merchandise printing, efficiency is the key to staying ahead of the competition. As the demand for personalized products continues to soar, businesses in this industry must find ways to streamline their workflows and optimize their resources. One innovative solution that has been gaining traction is the use of DTF (Direct to Film) gang sheets.

Understanding DTF Gang Sheets

Direct to Film (DTF) printing is a cutting-edge technology that has revolutionized the custom merch industry. Unlike traditional screen printing or heat transfer methods, DTF allows for the direct application of designs onto garments, eliminating the need for costly and time-consuming setup processes.

A DTF gang sheet takes this concept a step further by enabling the printing of multiple designs on a single sheet. This approach not only saves time and materials but also enhances the overall productivity of the printing operation. By grouping similar designs or complementary artwork together, businesses can maximize the use of their printing surfaces and minimize waste.

Benefits of Using DTF Gang Sheets

The adoption of DTF gang sheets in custom merch printing offers a multitude of advantages that can significantly impact a business's bottom line.

Cost-effectiveness

By optimizing the use of materials and reducing waste, DTF gang sheets help businesses save on the cost of consumables, such as ink, film, and garments. This translates to a more favorable profit margin and the ability to offer competitive pricing to customers.

Time Savings

The streamlined workflow enabled by DTF gang sheets can dramatically reduce the time required for each printing job. With fewer setups and faster turnaround times, businesses can take on more orders and improve their overall productivity.

Material Optimization

DTF gang sheets allow for the efficient use of printing surfaces, ensuring that every inch of the film is utilized. This minimizes material waste and ensures that businesses get the most out of their resources.

Versatility in Design

The flexibility of DTF printing, combined with the gang sheet approach, enables businesses to offer a wider range of design options to their customers. Clients can mix and match designs, experiment with different color combinations, and create unique product offerings.

Implementing DTF Gang Sheets in Your Workflow

Integrating DTF gang sheets into your custom merch printing workflow requires careful planning and organization. Here are some key considerations:

Planning and Organization

Effective implementation starts with a thorough understanding of your production needs and the types of designs your customers typically request. By analyzing this data, you can develop a strategic plan for organizing your gang sheets and optimizing your printing processes.

Design Considerations

When creating DTF gang sheets, it's essential to consider factors such as design compatibility, color palettes, and garment sizes. Thoughtful layout and arrangement can maximize the efficiency of each printing session.

Software and Tools

Specialized software and tools can greatly assist in the creation and management of DTF gang sheets. These solutions often include features like automated layout optimization, color management, and job tracking, streamlining the entire printing process.

Best Practices for DTF Gang Sheet Printing

To ensure the success of your DTF gang sheet printing operations, it's crucial to follow best practices in areas such as layout, color management, and quality control.

Optimal Layout Techniques

Carefully arranging the designs on the gang sheet can optimize material usage and minimize waste. Strategies like nesting, staggering, and considering garment sizes can all contribute to improved efficiency.

Color Management

Consistent color reproduction is essential for maintaining the quality of your custom merch. Implementing robust color management protocols, including calibration and profile creation, can help ensure accurate and vibrant results.

Quality Control Measures

Implementing rigorous quality control measures, such as pre-production testing and in-process inspections, can help identify and address any issues before they impact the final product.

Overcoming Common Challenges

While the benefits of DTF gang sheets are numerous, businesses may encounter some challenges during implementation. Understanding and addressing these obstacles can help ensure a smooth transition.

Addressing Registration Issues

Proper alignment and registration of designs on the gang sheet are crucial for achieving high-quality results. Investing in the right equipment and developing robust quality control procedures can help mitigate registration problems.

Handling Different Garment Sizes and Types

Custom merch printing often involves a wide range of garment sizes and styles. Adapting your DTF gang sheet design and printing processes to accommodate these variations can help ensure consistent and reliable results.

Balancing Quantity vs. Variety

Finding the right balance between producing large quantities of a few popular designs and offering a wider variety of options can be a delicate task. Careful analysis of customer demand and market trends can help businesses make informed decisions.

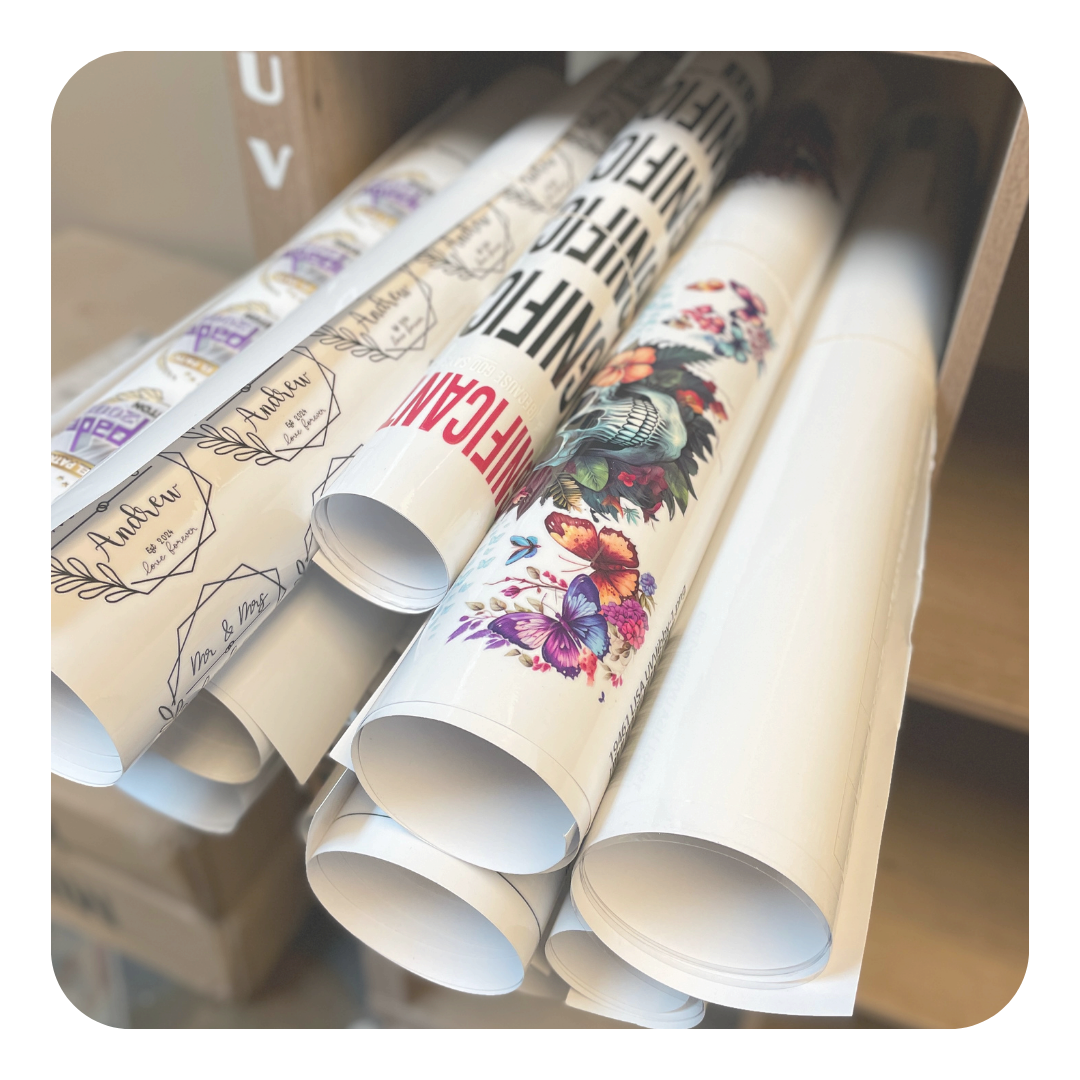

Case Studies: Successful Implementation of DTF Gang Sheets

To illustrate the real-world impact of DTF gang sheets, let's explore a few case studies:

Small Business Perspective

A local custom t-shirt shop, OreletPrint, faced the challenge of meeting the growing demand for personalized merchandise while maintaining profitability. By adopting DTF gang sheet printing, they were able to reduce material waste, streamline their workflow, and offer a broader range of design options to their customers. As a result, OreletPrint saw a significant increase in their profit margins and customer satisfaction.

Large-Scale Production Examples

In the world of high-volume custom merch printing, DTF gang sheets have proven to be a game-changer. A large-scale printing operation, specializing in event merchandise, was able to increase their daily output by 30% by implementing DTF gang sheet technology. This not only improved their bottom line but also allowed them to take on more orders and expand their client base.

Future Trends in DTF Gang Sheet Printing

As the custom merch industry continues to evolve, the role of DTF gang sheets is expected to become even more prominent. Here are some emerging trends to watch:

Technological Advancements

Ongoing innovations in printing equipment, software, and materials are likely to enhance the capabilities and efficiency of DTF gang sheet printing. Expect to see improvements in areas such as registration accuracy, color management, and automation.

Sustainability Considerations

As environmental consciousness grows, businesses in the custom merch industry will increasingly prioritize sustainable practices. DTF printing, with its reduced material waste and energy consumption, aligns well with this trend, making gang sheets an attractive option for eco-conscious companies.

Conclusion

In the fast-paced world of custom merchandise printing, efficiency is the key to success. By embracing the power of DTF gang sheets, businesses can streamline their workflows, optimize their resources, and deliver high-quality products to their customers. As the industry continues to evolve, the adoption of this innovative technology will undoubtedly play a crucial role in shaping the future of custom merch printing.